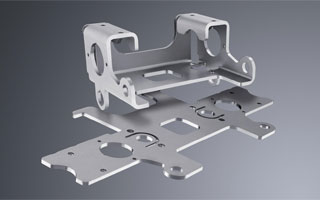

SUNGDONG TECH specializing in metal material processing and product manufacturing holds the know-how and passion required for

manufacturing all sorts of products made of metal materials.

The modern metal processing capability is determined based on whether or not state-of-the-art equipment is used.

SUNGDONG TECH promises to provide the best technology and competitiveness to customers through its continuous r

esearch and development and optimized equipment investments.

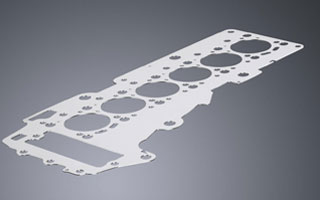

SUNGDONG TECH uses a 2D laser cutter(4000W ~ 8㎾) that accelerates

thin plate processing and enhances thick plate processing.

This laser cutter is capable of cutting metal plates with a thickness of 1mm as well

as aluminum/copper/stainless plates with a thickness of 25mm, and is also capable of

demonstrating narrow, precise cutting processing that boasts burr-free cut surfaces.

| Machine Type | Model | Processing Capacity | Manufacturer |

|---|---|---|---|

| Laser | TruLaser 3030 (5000W) | STEEL : 25T / SUS : 20T / AL : 12.7T | TRUMPF(Germany) |

| TruLaser 3030 fiber (4000W) | STEEL : 25T / SUS : 20T / AL : 15T / CU : 8T | ||

| TruLaser 5030 fiber (8000W) | STEEL : 25T / SUS : 40T / AL : 25T / CU : 10T |

World’s First Fiber Laser Cutting Machine(8㎾)

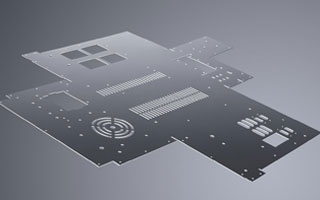

SUNGDONG TECH is capable of processing/manufacturing precision products based on the

combination of the followings: excellent technical prowess, state-of-the-art laser

cutting machines, and precision-processed bending machines.

SUNGDONG TECH manufactures precise, crack-free products according to customers’ diverse requirements.

| Machine Type | Model | Processing Capacity | Manufacturer |

|---|---|---|---|

| Bending | TruBend 5170 | 170T × 3M | TRUMPF(Germany) |

| TruBend 5130 | 130T × 3M | ||

| TruBend 7036 | 36T × 1M | ||

| AMADA RG25 | 25T × 1M | AMADA(Japan) |

High-efficiency Bender Demonstrating Optimized Productivity

Ultrahigh-speed Compact Bender Optimized to Super-precision Product Processing

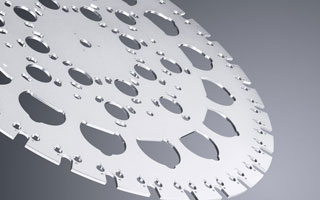

SUNGDONG TECH equipped with state-of-the-art NCT machines and laser-cutting machines is a company specializing in outsourcing processing.

Through accumulating excellent know-how on NCT processing techniques and securing the best processing technicians in the industry, SUNGDONG TECH was able to enhance its productivity to the utmost extent possible.

| Machine Type | Model | Processing Capacity | Manufacturer |

|---|---|---|---|

| NCT | AMADA VIPROS 357 | 30T × 1.2M(6T) | AMADA (Japan) |

| Shearing Machine | AMADA NS2535 | MAX 3.5㎜(T) × 2500㎜ | AMADA (Japan) |

| CNC TOP Deburring & Polishing Machine | MD5 CVV1350 | Manufacture width 1350㎜ | COSTA (Italy) |